Cut and sew is one of the most fundamental and traditional methods of garment production. As the name suggests, the fabric is cut according to patterns and then sewn together piece by piece. Unlike mass-produced, fully automated systems, cut and sew allows for more craftsmanship, control, and customization—essential for fashion brands looking for unique fits and details.

What Does “Cut and Sew” Mean?

In the world of apparel manufacturing, cut and sew refers to garments made from raw fabric cut in house and stitched together in the same facility or location. This contrasts with simpler methods like tagless printing or sublimation. A brand might request cut-And- Sew in items such as hoodies, jeans, swimwear, bras, or quilting because they require precise fabric handling and assembly.

Step-by-Step Cut- and- Sew Process

Below is a detailed breakdown of how cut and sew manufacturing works from start to finish:

1. Design & Pattern Making

- Create technical sketches and size templates.

- Use specialized pattern-making tools to produce cut templates in various sizes.

2. Fabric Selection & Preparing

- Select the right materials (e.g., knit fabric for hoodies, swimwear cloth).

- Lay out fabric on the cutting table.

3. Cutting

- Use manual or automated cutting tools to follow the pattern outlines.

- Cut all pieces needed: front, back, sleeves, waistbands, pocket panels, quilt panels, etc.

4. Sorting & Bundling

- Organize fabric pieces by size, color, or design.

- Bundle pieces together to streamline production flow.

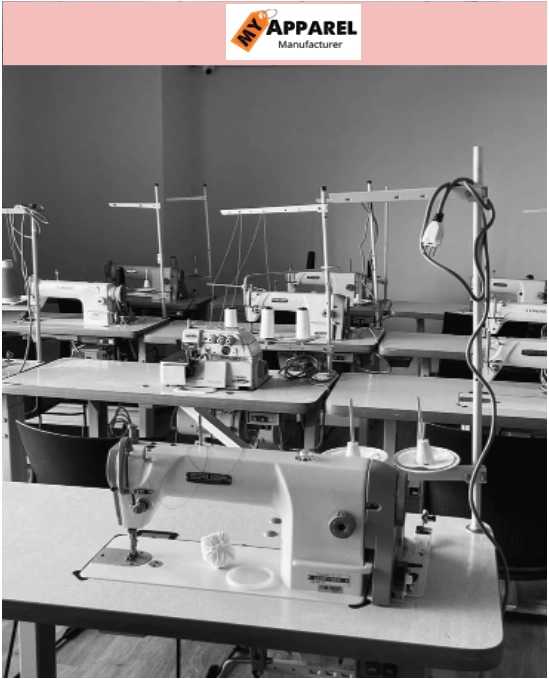

5. Sewing

- Skilled workers assemble bundles at sewing stations.

- Multiple machines may be used: flatbed, overlock, coverstitch, buttonhole, etc.

- For example, switch between fabrics like jersey, quilted cotton, or swimwear cloth depending on the garment.

6. Quality Control

- Inspect seam finishes, alignments, durability, and look for defects.

7. Pressing & Finishing

- Press garments, trim loose threads, trim foam inserts (for bras), and add tags.

8. Packaging

- Fold, bag, box, and label garments, ready for shipping or retail.

Why Choose Cut- And Sew?

Full Design Flexibility

Suitable for custom pieces like cut- and sew hoodies, cut and sew jeans, or swimwear. Choose fabrics, prints, foam inserts (e.g., cut and sew bra foam), and trims with control.

Better Quality Control

Pieces are cut and sewn under the same roof, reducing errors and improving crafting consistency—ideal for branded clothing.

Perfect for Small-Batch Clothing Brands

Brands can benefit from using local cut and sew studio services in cities like Pittsburgh or Teaneck without needing huge volumes.

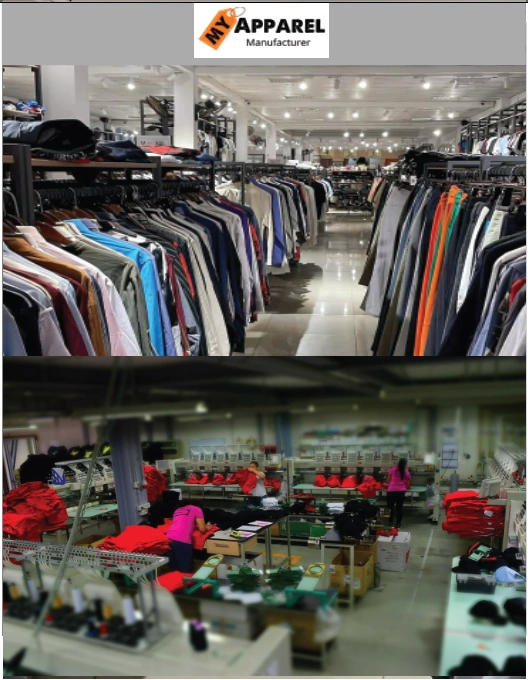

Global Fabric Sourcing

Fabrics may be sourced in the U.S., Asia, or Europe and brought to cut and sew clothing manufacturers, as seen in places like Orange County or Bali swimwear factories.

Real-World ‘Cut and Sew’ Examples

- Cut & Sew Hoodies or Jeans – Ideal for streetwear brands needing unique silhouettes and detail work.

- Cut & Sew Swimwear – Requires specialized fabrics (e.g., from swimwear clothing factory in Bali) and precision sewing.

- Cut & Sew Quilts – For bedding brands, which need durability and crafted uniformity in quilting.

- Cut & Sew Bras – This includes foam lining, shaping, and reinforced seam work.

- Cut & Sew Activewear or Knits – Uses stretch fabrics, flatlock seams, and often complex paneling.

Choosing the Right Cut and Sew Manufacturer

When looking for a cut and sew partner, consider:

- Location & Specialty

- Do you need activewear fabrics, quilting, or swimwear materials?

- Are local MOQ or customs key for your brand?

- Quality Standards

- Ask for samples for stitching, foam inserts (bras), and press finishes.

- Minimum Quantities

- Some studios offer 50–100 unit batches; others require larger loads. For example, certain Bali swimwear facilities may specialize in mid-size volumes.

- Technology Use

- Do they use auto-cut machines? CAD-designed patterns?

- Cost & Lead Time

- Cutting and sewing manually may cost more but offer better control and quality.

- Quick sampling: 1–2 weeks; mass production: 4–8 weeks depending on complexity.

Cut and Sew vs. Fully Fashioned/Blank Production

| Aspect | Cut & Sew | Fully Fashioned / Blanks |

| Design Freedom | High – custom panels and styles | Low – pre-sewn fabric pieces |

| Cost per Unit | Higher for small batches | Lower for large volumes |

| Quality Control | Full oversight in your facility | Opaque—fabric pre-made by others |

| MOQ Flexibility | Studio-level flexibility available | Large batch MOQ typically required |

Tips for Brands Using Cut and Sew

- Use Templates and Markers

Cut and sew manufacturers often create layout markers to maximize fabric usage and reduce waste. - Plan for Trims & Finishing

You may need to supply buttons, labels, foam lining, or special fabrics (like quilted panels). - Request Pre/Post-Cut Samples

Review fabric swatches and mini-cut samples before full cut run. - Invest in Quality Control

Hire QC during final sewing or press steps to catch seam flaws or miscuts. - Scale With Confidence

Many studios offer modular growth: “cut & sew near me” can evolve into larger factory production.

FAQs About Cut and Sew Clothing

Q1: Can I use cut and sew for swimwear and activewear?

A: Definitely—cut and sew allows you to customize shape, fabric elasticity, and panel placement for items like swim trunks, rash guards, or athletic tops.

Q2: What’s the minimum order for cut and sew?

A: Some studios support orders as low as 30 – 50 units; larger factories may require 500+.

Q3: Is cut and sew more expensive?

A: Typically yes for small quantities due to labor intensity—but quality and branding control make it worthwhile.

Q4: How long does the process take?

A: Sampling usually takes 2–3 weeks. Full production takes 2–3 weeks depending on garment complexity and volume.

Q5: How is cut and sew different from sublimation or DTG printing?

A: Cut and sew involves actual fabric shaping and tailoring; printing adds graphics to the finished garment but doesn’t alter its built structure.

Final Thoughts

Cut and sew clothing manufacturing is perfect for brands that value quality, customization, and design control. Whether you’re launching hoodies, swimwear, or custom bras, this method gives you craftsmanship, unique style, and the freedom to build a brand that stands out.

By understanding the full process—from pattern making and layout cutting to sewing, pressing, and finishing—you can effectively partner with the right cut and sew manufacturer, whether it’s a boutique studio, swimwear factory in Bali, or large garment facility in the U.S. or UK.